We are a source supplier of PDMS films, supporting various custom sizes to meet your laboratory requirements.

Polydimethylsiloxane (PDMS), a silicone - based polymer, has established itself as an essential material in university laboratory research. Here's a comprehensive look at its properties and applications:

| Property | Value | Property | Value |

| Hardness (Shore A) | 42 | Refractive Index | 1.41 |

| Tensile Strength (MPa) | 4.2 | Cytotoxicity | Non - toxic |

| Elongation at Break (%) | 180 | Dielectric Constant (100kHz) | 2.7 |

| Elastic Modulus (MPa) | 0.6 | Volume Resistivity (Ω·Cm) | 10¹⁵ |

| Light Transmittance % (2mm) | 94 | Dielectric Strength (kv/mm) | 20 |

| Temperature Resistance (°C) | -45~200 | Dielectric Loss (100kHz) | 0.001 |

| Water Vapor Transmission | 650 cm³/m²/24h at 50μm | Thickness (μm) | 15-30-50-100-150-200 - 300 - 400 - 500 - 600 |

| Dimensions (mm) | 200-150 or 200-300 | Dimensions (inches) | 7.8*5.9 or 7.8*11.8 |

1. Physical Properties:

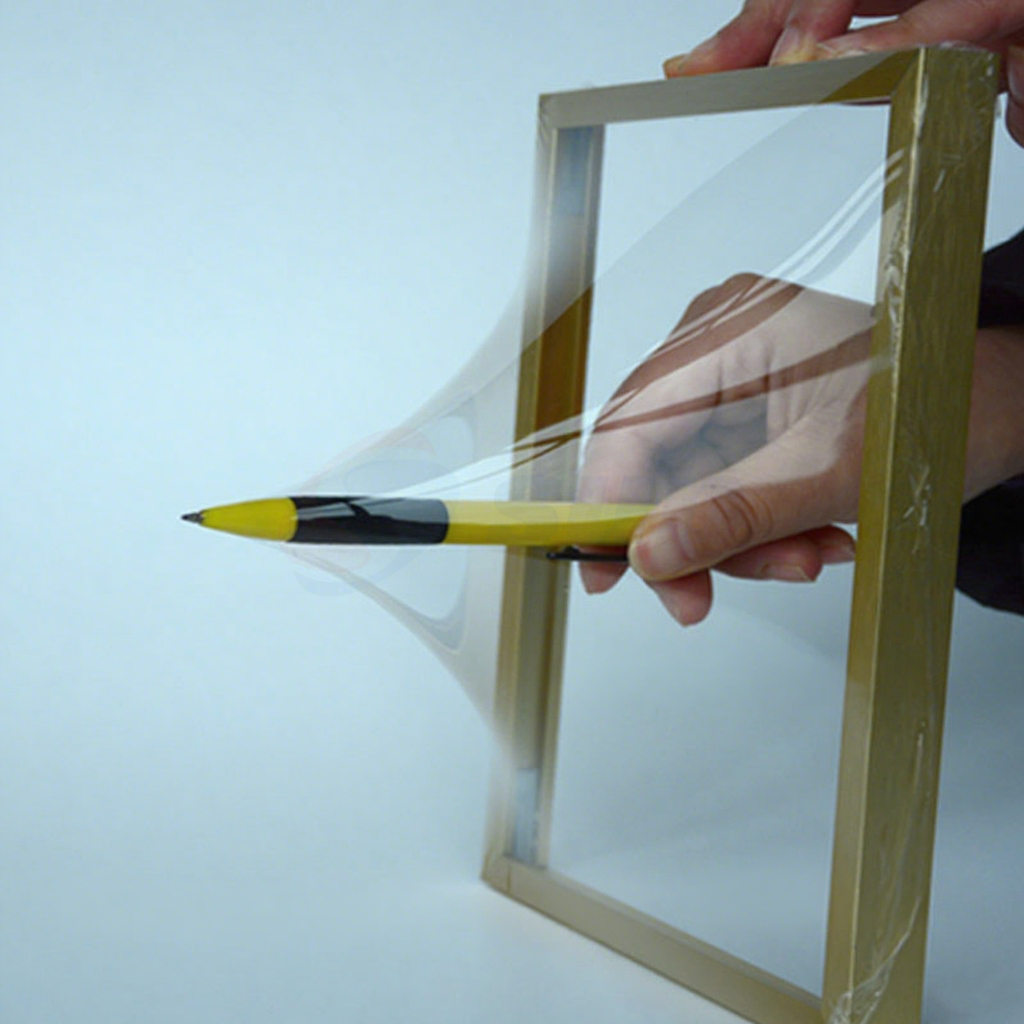

- Formability & Flexibility: In its uncured state, PDMS has low viscosity, enabling effortless casting and molding into complex shapes—ideal for custom - designed lab setups. Once cured, it transforms into a flexible elastomer with adjustable hardness (e.g., Shore A hardness values like 42 are achievable). This adaptability suits experiments ranging from gentle cell manipulation to mechanical stress tests.

- Transparency & Thermal Stability: PDMS exhibits exceptional transparency (up to 94% light transmittance for 2mm - thick films), facilitating real - time optical observation. It maintains flexibility across a wide temperature range (typically - 45°C to 200°C), ensuring reliability in experiments with varying thermal demands.

2. Chemical Properties:

- Inertness & Compatibility: Chemically inert, PDMS resists degradation from most chemicals, solvents, and biological fluids—critical for experiments involving diverse reagents. Its low surface energy imparts hydrophobicity, useful for creating microfluidic channels that repel aqueous solutions.

- Surface Functionalization: PDMS surfaces can be modified (e.g., via plasma treatment) to introduce reactive groups, expanding compatibility with other materials or biomolecules for advanced bioengineering and sensing applications.

3. Application Fields:

- Microfluidics & Lab - on - a - Chip: PDMS is the industry standard for microfluidic devices. Soft lithography allows fabrication of intricate channel networks for cell culture, chemical synthesis, and high - throughput analysis. Its transparency enables real - time monitoring of fluid dynamics and reactions.

- Biomedical Research: Biocompatible (non - cytotoxic) PDMS serves as scaffolds for tissue engineering, supporting cell growth and differentiation. It also mimics biological environments for in vitro drug testing, accelerating preclinical research.

- Optics & Photonics: With a refractive index of ~1.41 and high transparency, PDMS is used to build optical components (waveguides, lenses) for photonics research, enabling studies in light - matter interactions and micro - optical systems.

- Material Science: As a model elastomer, PDMS helps investigate mechanical properties (adhesion, friction) at micro/nanoscales, informing the development of new coatings, soft robotics, and advanced materials.

PDMS' unique blend of physical and chemical traits makes it a versatile tool across disciplines—from biology to engineering—driving innovation in university lab research. Whether crafting microfluidic devices or studying biomaterial interactions, PDMS empowers researchers to push the boundaries of scientific exploration.

Office Photo

Exhibition

Contact: Bruce Liu

WhatsApp: +86-18059149998

Tel: +86-18059149998

Email: sales@supsemi.com

Add: Room 1402, Building 1, No. 89 Xibeilu, Xishancun, Xibei Street, Xinluo District, Longyan City, Fujian Province

We chat