【Cutting Precision】Less than 0.5mm

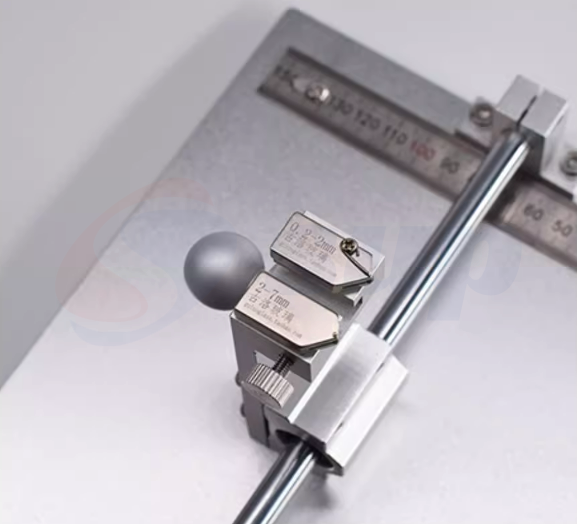

【Cutting Thickness】0.4 - 7.0mm

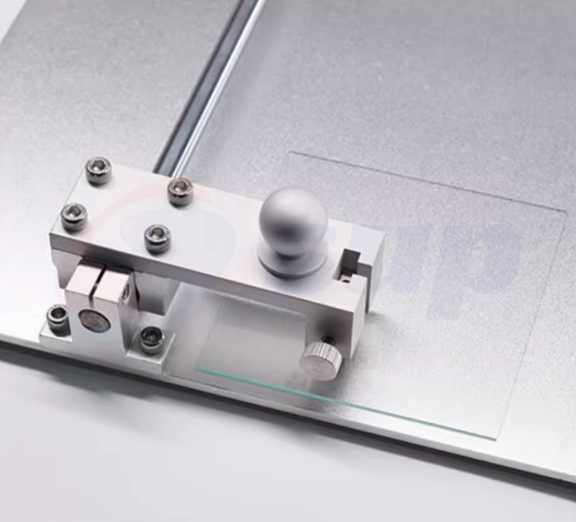

【Product Composition】Consists of three parts: cutting workbench, positioning device, and cutting component, and can be disassembled by oneself.

【Applicable for Cutting】Suitable for glass materials such as ITO/FTO conductive glass, AZO conductive glass, thin glass substrates, quartz glass, and silicon wafer glass.

Product Features:

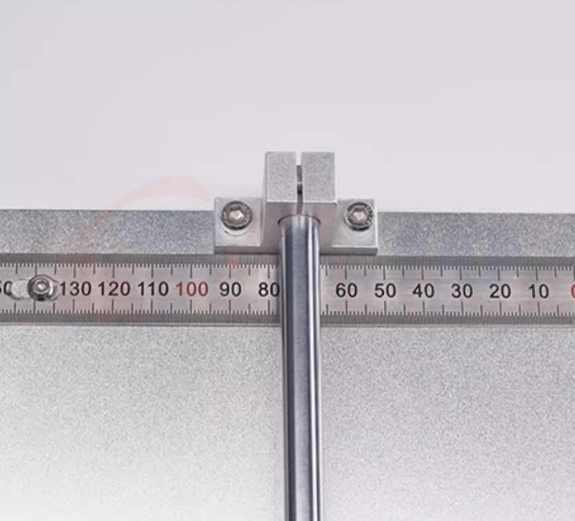

1. Fine cutting, with scales as small as 0.1mm; Customizable in size and easy to carry;

2. Aluminum alloy tabletop without deformation and long service life; Graphite bearings operate smoothly and require no maintenance;

3. Imported customized cutter wheel, with neat cuts and simple operation, improving cutting speed;

4. Make full use of each piece of glass original sheet, reduce the waste of leftover materials and lower costs;

5.The cutting tool bit has fast cutting speed, high precision, low wear and good cutting quality.

Product Size:

| Overall Dimensions | 500*470mm | 350*250mm | 190*175mm |

| Cutting Range | 400*500mm | 170*350mm | 100*100mm |

| Packing Dimensions | 580*550*170mm | 420*310*140mm | 200*250*70mm |

| Product Weight | 8 - 9KG | 3 - 4KG | 1 - 2KG |

| Product Model | GL - 913545 | GL - 912535 | GL - 911917 |

Installing the Cutter Head:

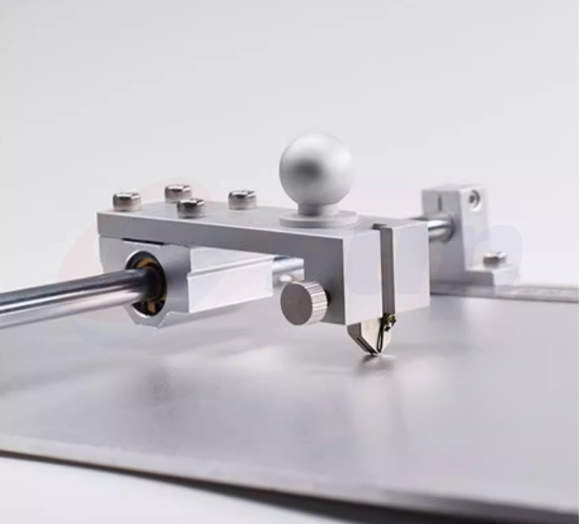

1. Before installing the cutter head, ensure the cutting tool handle moves smoothly in the bearing.

2. Place the glass to be cut on the cutting table, aligning the top with the scale ruler.

3. Face the side of the cutter head with the wound iron wire outward, then install the cutting head.

4. Place the cutter head on the glass to be cut. Adjust the clamping depth of the cutter head, ensuring the cutting component is absolutely perpendicular to the panel. A try square can be used for measurement.

Cutting the Glass:

1. Place a clean A4 printing paper on the tabletop to prevent scratches on the glass and the cutting worktable panel.

2. Put the glass to be cut on the cutting worktable, aligning the top with the scale ruler.

3. Install a suitable cutter head and adjust it to be perpendicular (at a 90 - degree angle) to the cutting tabletop.

4. Align the left or right end with the size scale to be cut; the red 0 - scale mark is the cutting line. When cutting glass, the force of the cutter is crucial. It's best to do it in one smooth motion: place and lightly press the glass to be cut, then draw the cutting line on the glass from top to bottom. Avoid scratch joints, as they may cause the glass to fork and break.

5. Cut the long and short sides in sequence according to the required size.

6. After cutting, you can choose to remove the cutting head and store it separately. Or, if not removing it, lift the cutting head to be perpendicular to the cutting worktable. This avoids damage from extrusion between the cutting head and the tabletop and protects the cutting panel from scratches.

7. Place the glass in a safe location after finishing.

Office Photo

Exhibition

Contact: Bruce Liu

WhatsApp: +86-18059149998

Tel: +86-18059149998

Email: sales@supsemi.com

Add: Room 1402, Building 1, No. 89 Xibeilu, Xishancun, Xibei Street, Xinluo District, Longyan City, Fujian Province

We chat